The basics of asphalt used in roofing

By Mike Anderson, P.E.

Classes are in session at college campuses throughout the United States. Every year, new students arrive with aspirations of becoming an asphalt doctor, asphalt lawyer or asphalt engineer. Some will choose the natural sciences like asphalt chemistry. Others may choose to study asphalt business or asphalt marketing. Unfortunately, the field of asphalt psychology hasn’t really drawn much interest. The psychology of asphalt technologists (who write magazine articles), however, seems to be a potential growth area. I know my wife would gladly offer a yearly scholarship to this field of study. Regardless of which field of study a student wishes to pursue in the broad area of asphalt, they have to start off with the basics. That means the “100” level classes – with the “101” classes usually being the most basic. That being said, it seems an appropriate time to look at the basics of asphalt used in roofing applications, such as shingle manufacture.

BACK IN TIME

What I remember from my school days was that we usually started a new course or textbook with a little history. So, let’s start with the 1800s to see how asphalt roofing and asphalt shingles evolved.

In the early days of the 1800s in the United States, before asphalt shingles were invented, roofers would often lay fabric in place and coat the fabric with a sticky substance like pine tar. In the 1840s a technique learned from “…a roofer in Newark became the basis for a roofing business begun in Cincinnati by Samuel M. and Cyrus M. Warren.”[1] The method used by the Warrens involved the use of “heavy paper, covered with pine tar and sprinkled with sand.” In 1847, the Warrens elected to use coal tar – which was a waste byproduct for the gas light industry – to replace the more costly pine tar in their roofing system.

Although coal tar was initially considered just a byproduct with little useful value, the developing chemical industry became a more lucrative outlet for its use. As such, supply diminished and prices rose, leaving the roofing industry to seek another source of adhesive material for their roofing systems. The Warrens continued to be a leader in the industry in product development, finding that Trinidad Lake asphalt could be blended with byproducts of oil refining to produce an easy-to mix roofing pitch. [1] In the 1860s, the growth of the petroleum industry created an abundant source of asphalt that could serve as a substitute for coal tar in roofing systems. By the close of the century, composition roofing products used in roofing for all types of buildings were mostly made using cotton-based, “rag” felts, which were saturated by petroleum asphalt and surfaced with “slate” chips – the predecessor of the asphalt shingle.

In 1903, Henry Reynolds – a roofing contractor from Grand Rapids, Michigan who has been credited with the invention of the roofing shingle – began cutting asphalt saturated rolls that had been surfaced with stone into individual “shingles.” The first shingles were cut by hand into 8” x 16” pieces. Twelve years later machinery was perfected to use a roller-die to cut individual shingles from a continuous ribbon of asphalt saturated felt. In the 1920s the first strip shingle, known as the Neposet Twin, was created by Bird and Son. It was a 12.5” x 20” shingle with a cut out in the middle. By the 1950s, the industry had established standard asphalt shingles at 12” x 36” with a three-tab format.

While the shape and dimensions of the shingle were undergoing changes, so too was the composition. As happened with the use of pine tar (first) and coal tar (later) the increasing cost of cotton used as the “rag” felt led to experimentation with alternatives. By the end of the 1940s the roofing industry had abandoned the use of cotton-based “rag” felts and switched to mostly celluloid-based felts. The experimentation continued from there beginning in the 1960s, evaluating fiberglass as a potential replacement material for felts. By the mid-1980s the roofing industry had rapidly converted to fiberglass mats as replacement for organic felt and by the time MTV started showing more reality shows and less music videos fiberglass-based shingles had become the dominant type of product with over 90 percent of the shingle market.

THE COMPOSITION OF COMPOSITION ROOFS

The roofing market is divided into two general categories: steep-slope and low-slope. Steep-slope roofing includes coverings installed on slopes exceeding 14 degrees. This is usually associated with residential roofing and, by connection, shingles. Low-slope roofing includes water impermeable or weatherproof systems installed in slopes that are less than or equal to 14 degrees. This type of roofing is usually associated with commercial roofing. [2] With this categorization, it is easy to understand that steep slope roofing is the dominant type of product with over 75 percent of the total roofing market. It is estimated that four out of five homes are roofed with asphalt shingles. [3]

Asphalt shingles are composed of the following:

• Base material (fiberglass felt) to provide strength.

• Coating asphalt (with modifiers as desired) to provide weather resistance and adhesion for the surfacing material.

• Mineral filler to improve fire resistance, wind resistance, and weathering.

• Surfacing material, generally mineral granules, to provide resistance to impact (e.g., hail) and ultraviolet degradation, and to improve fire resistance.

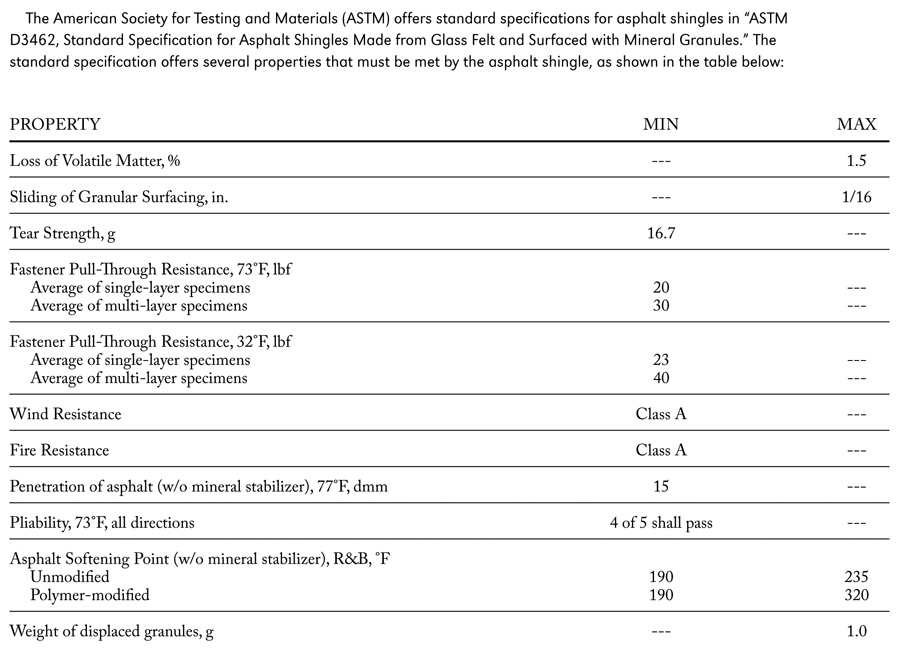

As seen in the table, there are two principal properties required that are solely related to the coating asphalt used in the shingle manufacture: Penetration at 77°F and Softening Point (Ring and Ball). These two properties provide some general indication of the consistency (stiffness) of the asphalt at intermediate and high temperatures, but don’t tell the whole story about whether or not a particular asphalt will make a good shingle coating.

ACKNOWLEDGMENTS AND REFERENCES

The information in this article was derived from the references shown below and from the “Roofing 101” presentation conducted at the Asphalt Institute’s Annual Meeting in 2012. Special thanks go to the members of the Asphalt Institute Roofing Technical Advisory Committee – specifically Andrew Ford, Mike Franzen, Greg Malarkey, Andrew Parker and Keith Stephens for their input.

[1] From Asbestos to Zinc: Roofing for Historic Buildings, United States National Park Service, www.nps.gov/history/hps/tps/roofingexhibit